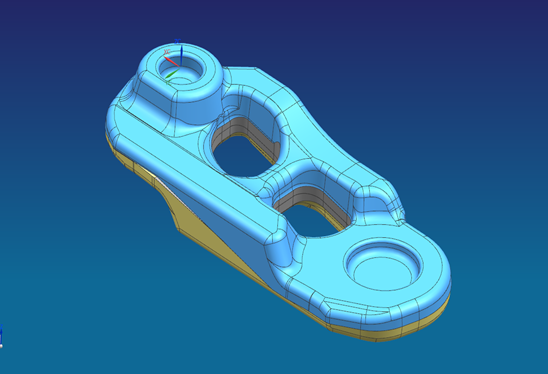

Forging is a processing method that uses forging machinery to exert pressure on metal billets to produce plastic deformation to obtain forgings with certain mechanical properties, certain shapes and sizes, and is one of the two components of forging (forging and stamping).

Our factory covers an area of 120 acres, plant 30,000 square meters, the main business for transmission parts precision forging blank (including isothermal normalizing, fine turning)

Precision forging equipment: 400T, 630T, 1000T, 1600T, 2000T and other 8 electric helical lines, 2 hydraulic die forging lines, 3 wedge rolling shaft lines, 2 Japanese Mori iron cold forging lines;

Machining equipment: 110 sets of CNC lathes, deep hole drilling, milling machines and machining centers;

Heat treatment equipment: 2 isothermal normalizing lines, 1 vacuum pit furnace.

Main customers:

Jinan Heavy Duty Truck, BYD, Weichai, Luoyang Yituo, Luoxiang NTN, Wuzhou New Spring, Schaeffler (Taicang), etc.

|

|

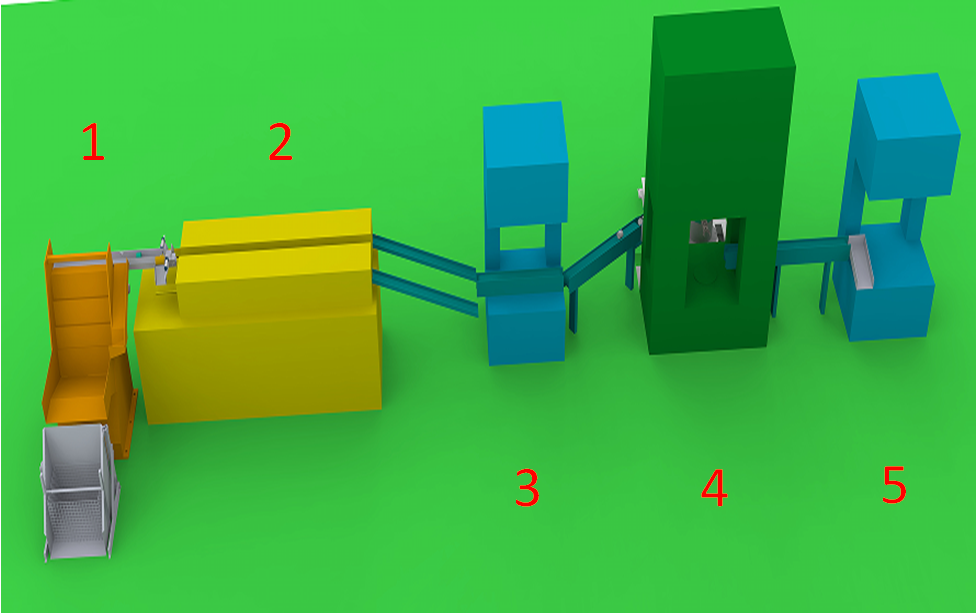

Feeding: automatic sorting machine

Heating: through medium frequency induction furnace

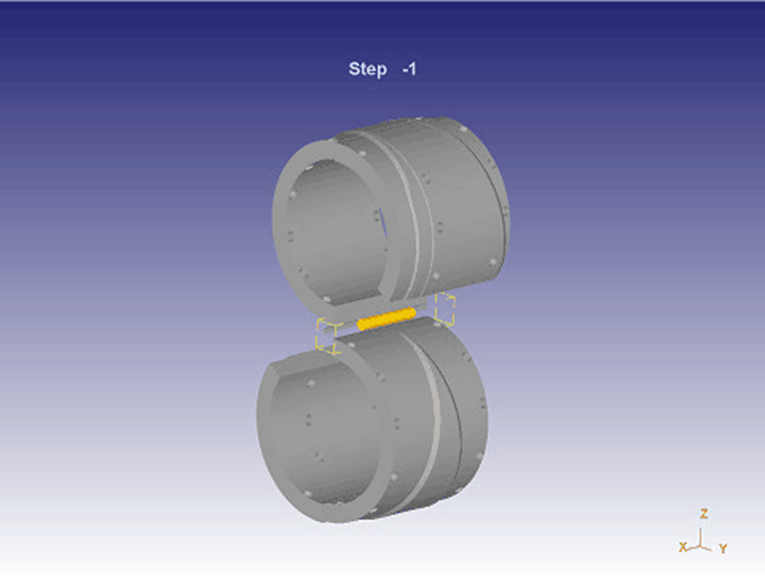

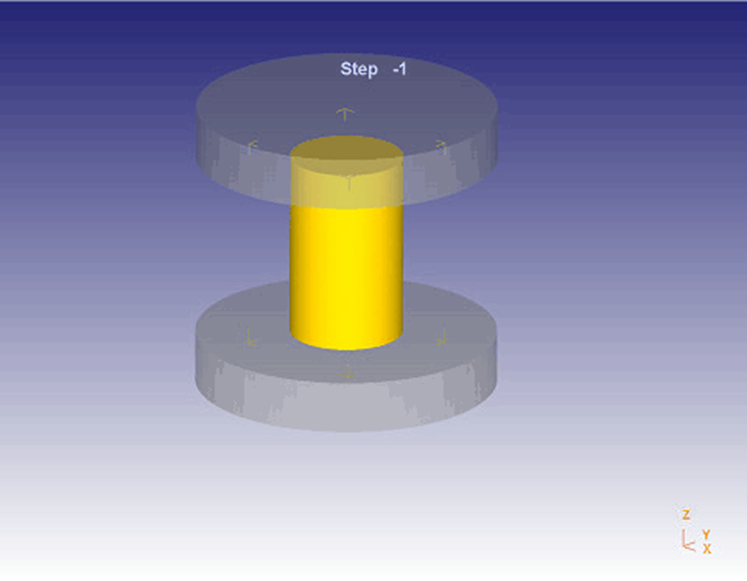

Preforging: closed type single point press

Final forging: electric screw press

Punching: single point closed type press

|

|

|

|